山东安立泰泵业股份有限公司

电话:0537-3205528

营销总监:185-5370-1777

传真:0537-6258619

全国服务热线:400-618-3816

邮箱:jiningantai@163.com

地址:山东省济宁市鱼台经济开发区

Copyright @ 2019 山东安立泰泵业股份有限公司 版权所有 鲁ICP备14036540号-1 网站建设:中企动力 济南 后台管理

BHG high tension cable connection box

Use and scope of application

1, overview:

BHG1 series mining vibration proof type high voltage cable terminal box (hereinafter referred to as the junction box) is suitable for containing explosive gas (methane), a mixture of coal dust in coal mine underground, in AC 50Hz, voltage 3.3kV, 6kV and 10kV power supply network for the cable connection.

The series high-voltage junction box according to GB, 3836-2010 MT/T1100-2009 design, manufacture and inspection, product quality in line with the above standards.

2, the use of conditions

A, altitude is not more than 2000m;

B, ambient temperature is -20 degrees C to +40;

C, air relative humidity is not more than 98% (+25 degrees C);

D, containing explosive gas (Jia Wan), the coal mine coal dust mixture;

E, where there is no significant shaking or violent shock;

F, pollution level: 3;

G, installation category: III.

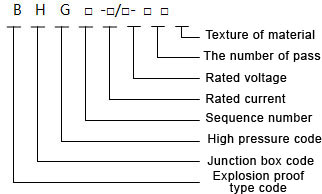

Two, model and its meaning

Model meaning

Three, explosion-proof form, mark:

Product type explosion-proof mark: ExdIMb

Explosion proof type: mine explosion proof type

Four, the implementation of standards:

MT/T1100-2009,

GB3836.1-2010 explosive environment - part first: General requirements for equipment

GB3836.2-2010 explosive environment in second parts: from the explosion-proof enclosure "d" protection of the equipment

Q/AT067 - 2012

Five, product size, weight, model specifications and its main technical parameters:

5.1 product size:

Size: 780mm * 300mm * 220mm * 900mm * 420mm * * 280mm

5.2 product weight:

53Kg-80Kg

5.3 product model specification see Table 1

|

Product model |

Rated voltage(kV) |

Rated current(A) |

The number of pass(G) |

|

BHG2-400/3.3-2G |

3.3 |

400 |

2 |

|

BHG1-315/6-2G |

6 |

315 |

2 |

|

BHG1-400/6-2G |

6 |

400 |

2 |

|

BHG1-315/10-2G |

10 |

315 |

2 |

|

BHG1-400/10-2G |

10 |

400 |

2 |

|

BHG2-400/3.3-3G |

3.3 |

400 |

3 |

|

BHG1-315/6-3G |

6 |

315 |

3 |

|

BHG1-400/6-3G-4G |

6 |

400 |

3-4 |

|

BHG1-500/6-4G |

6 |

500 |

4 |

|

BHG1-315/10-3G |

10 |

315 |

3 |

|

BHG1-400/10-3G-4G |

10 |

400 |

3-4 |

|

BHG1-500/10-4G |

10 |

500 |

4 |

5.4 rated short-time withstand current and rated peak withstand current see Table 2

|

Product model |

2S rated short-time withstand current |

Rated short-time withstand current time(S) |

Rated peak withstand current |

|

BHG1-400/3.3-2G |

6.3 |

2 |

15.75 |

|

BHG1-315/6-2G |

4 |

10 |

|

|

BHG1-400/6-2G |

6.3 |

15.75 |

|

|

BHG1-315/10-2G |

4 |

10 |

|

|

BHG1-400/10-2G |

6.3 |

15.75 |

|

|

BHG2-400/3.3-3G |

6.3 |

15.75 |

|

|

BHG1-315/6-3G |

4 |

10 |

|

|

BHG1-400/6-3G-4G |

6.3 |

15.75 |

|

|

BHG1-315/10-3G |

4 |

10 |

|

|

BHG1-400/10-3G-4G |

6.3 |

15.75 |

|

|

BHG1-500/6-4G |

6.3 |

15.75 |

|

|

BHG1-500/10-4G |

6.3 |

15.75 |

5.5 the rated insulation level is shown in Table 3

|

Voltage level(kV) |

Power frequency withstand voltage(kV) |

Lightning impulse withstand voltage(kV) |

|

3.3 |

18 |

20 |

|

6 |

23 |

40 |

|

10 |

30 |

60 |

Six, use and maintenance

6.1 read the instructions carefully before use.

6.2 in the maintenance and repair: no charged open! No damage to the explosion surface! The introduction of the device must be compacted!

6.3 before installing the cable wire should check whether the network voltage is consistent with the junction box rated voltage, and check the junction box parts are not damaged, if there is, it should be repaired or replaced in order to connect.

6.4 installation

6.4.1 in front of the operation to deal with cable carefully examined, the jacket should be in good condition, the core wire should be no moisture intrusion, and check the connector sign cards, nameplate, warning signs is complete, and then use tools or special tools will each part apart.

According to the requirements of 6.4.2 cable outer sheath and cut wire armoured.

6.4.2 bracing wire to wire to roll out a conical tail stuffed, rotating cone armoured evenly spread so far, then the pressure sleeve by a bolt fixed to live, to cut long steel wire armored.

6.4.3 peel sheath and adjustment of the shielding layer core wire length, namely the main core wire in left within the tapered tail end about 235 mm strengths truncated core line at the end of the insulation, the strip shielding layer twisted into a bundle nose line well, the nose line set in the wiring bolts impacted by a nut.

The shielding layer and the ground core are fixed on the ground base by 6.4.5.

6.4.6 above work is completed, according to the open the time order of sequence fit, fit in the process should be careful never bumps across the surface of the explosion.

6.5 should be cut off the power supply before the removal of the cable wire, (maintenance should also cut off the power supply under the premise of dismantling the cable wire).

6.6 the cable wires should be properly fixed to the connecting post, no loosening of the phenomenon, and should check whether the electrical gap and the distance from the standard to meet the standards.

6.7 where not connected to the cable through the opening end was applied on the sealing ring, a blocking plate, a washer, blocking the compression nut or pressure plate, pressing, so as not to affect the explosion-proof performance.

6.8 the use of the maintenance process should pay attention to the protection of the explosion-proof surface from damage and corrosion.

6.9 regularly check the introduction of the device sealing ring, sealing gasket joints, if the seal ring, seal gasket aging phenomenon should be replaced immediately.

Seven, failure analysis and troubleshooting:

7.1 using the cable diameter is enough but the use of the process of heating phenomenon, check whether the cable is compressed, such as loose and then pressing can be.

7.2 the use of the process of flashover, check the connection seat is damaged if there is any damage to the immediate replacement can be.

Eight, maintenance and maintenance

8.1 after the installation of the junction box, generally do not need daily maintenance.

8.2 often wipe the dust removing shell to avoid high temperature.

8.3 each use of the first quarter of the explosion-proof surface maintenance.

Nine, matters needing attention

9.1 terminal box after the failure of the whole proposal used downhole in change, there will be trouble connecting to the mine inspection on cassette.

9.2 the connection box is disassembled to protect the explosion-proof surface and the main components, so as to prevent the explosion and cause damage, the connection seat and the sealing ring are damaged and replaced in time.

Ten, packaging, transportation and storage

10.1 after the inspection of qualified products should be together with the technical documents into the plastic bag, and then into the packing box, the packaging should be firm and reliable.

10.2 technical documents and accessories supplied with the product.

A) product qualification certificate or quality assurance;

B) instructions for use;

C) packing list;

Accessories, bags and accessories, D.

10.3 the packing of the product shall meet the requirements of transportation and handling, and shall ensure that the products are not damaged during the normal transportation.

10.4 the outside of the product packaging box with the words and signs:

A) product name and model;

B) main technical parameters, receipt and delivery unit name and address;

C) packing quantity;

D) the "long and wide" size of the packing box;

E) pack years

Name and address, post code of f;

Net or gross weight, kg g);

(I) receiving unit name, address (zip code) and arrival;

The packing box 10.5 in the process of transportation not inverted, upside down, not suffer a strong jolt, vibration, collision and snow or rain.

Products should be stored in the absence of rain and snow invasion, good ventilation conditions, air does not contain acid, alkali and other corrosive gas or dust.

10.6 stored in the environment (0-40) C, dry, clean and well ventilated, non corrosive medium in the warehouse.

Eleven, maintenance and after-sales service

11.1 factory responsible for the maintenance of the product.

11.2 this product customer service quality problems occur within one year (human factors) is responsible for replacement.

11.3 this product warranty within two years, to provide technical services for life.

11.4 the factory is willing to provide users with technical advice and services.

Twelve, random accessories and ordering instructions:

1, ordering instructions:

Type of starter;

Operating voltage, if not specified, the factory in accordance with 1140V configuration;

Order number.

2, random accessories

Product qualification certificate;

A copy of the instruction.