山东安立泰泵业股份有限公司

电话:0537-3205528

营销总监:185-5370-1777

传真:0537-6258619

全国服务热线:400-618-3816

邮箱:jiningantai@163.com

地址:山东省济宁市鱼台经济开发区

Copyright @ 2019 山东安立泰泵业股份有限公司 版权所有 鲁ICP备14036540号-1 网站建设:中企动力 济南 后台管理

ZBZ4.0 lighting integrated protection 39-40

First, an overview

1.1 scope of application

ZBZ-4.0/1140 (660) m mining segment burst type signal lighting transformer integrated protection device (hereinafter referred to as integrated device), the protective device applicable in explosive gas environment of methane and coal dust in coal mine underground, in 133v power supply network for lighting and signal load power supply, with control and short circuit, overload, leakage protection.

1.2 applicable conditions

A, not more than 1000 meters above sea level;

B, ambient medium temperature of -20 degrees C - +40;

C, the relative humidity of the surrounding medium is not more than 95% (25 degrees C);

D, can be used for the mine with coal dust and gas in danger;

E, in the absence of sufficient corrosion of the metal and the destruction of the insulation of the gas or steam environment;

F, in the absence of a strong vibration and the installation of the installation position with the vertical tilt of no more than 15 degrees;

G, in places with fire and rain invasion; h, a power supply for AC 50Hz, rated voltage of 1140; or 380V 660V system.

1.3 explosion-proof type: mine explosion-proof type

Explosion proof mark: ExdIMb

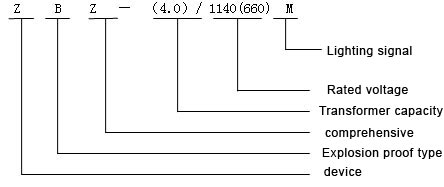

1.4 product models and their implications

1.5 product implementation standards:GB3836-2011 MT625-2007 Q/AT065-2012

Two, technical characteristics

2.1 basic parameters:

Table 1 and table 2 are the main technical parameters of 2.1.1 integrated device.

Table 1

|

Model |

Main transformer parameters |

|||||

|

Rated capacity |

Rated voltage |

Rated current |

Connection mode |

Allowable temperature rise K |

Insulation grade |

|

|

ZBZ-4.0M |

4.0 |

1140、660/133 |

3.49、6.1/17.36 |

Y△/△ |

85 |

B |

Table 2

|

Selection of cable cross section |

Lighting cable protection distance m |

Signal cable protection distance m |

|

ZBZ-4.0M |

ZBZ-4.0M |

|

|

Current setting 20A |

Current setting 5.5A |

|

|

6.0 |

600 |

1800 |

|

4.0 |

400 |

1400 |

|

2.5 |

250 |

850 |

|

1.5 |

150 |

600 |

|

1.0 |

100 |

400 |

2.1.2 The action time of short circuit leakage protection is shown in table 3.

|

Type No. |

Lighting short action time |

Signal short action time |

Leakage protection action |

|

ZBZ-4.0M |

≤0.25 |

≤0.4 |

≤0.25 |

2.1.3 The setting value of the leakage and the leakage locking are shown in table 4.

|

Model |

Setting of leakage resistance(Dan Xiang)kΩ |

Leakage locking action value(Dan Xiang)kΩ |

Risk indication of cable insulation(Dan Xiang)kΩ |

|

ZBZ-4.0M |

1.5 |

3±1 |

10±2 |

2.2 power rating: 50Hz.

2.3 devices for long-term work system.

2.4 technical requirements

2.4.1 the equipment should meet the requirements of this standard.

2.4.2 and in accordance with the provisions of the procedures specified in the state and the approval of the examination and approval of the units of the drawings and documents made, and made the inspection unit issued explosion-proof certificate".

The dielectric performance of the 2.4.3 integrated device shall be subject to the power frequency withstand voltage of AC 1min, which will last for 50Hz without breakdown.

2.4.4 the power frequency withstand test value shall be in accordance with the provisions of table 4.

|

Rated insulation voltage of circuit ui (V) |

Power frequency voltage withstand test voltage (AC RMS)(V) |

|

ui≤60 |

1000 |

2.4.5 control circuit and auxiliary circuit connected to the main circuit, the power frequency withstand voltage test voltage should be in accordance with the provisions of table 5

|

Control circuit and rated insulation voltage ui (V) |

Power frequency voltage withstand test voltage (AC RMS)(V) |

|

ui≤60 |

1000 |

|

Ui>60 |

2 ui+1000(Not less than 1500) |

2.4.6 main transformer its power frequency withstand voltage test voltage value shall comply with the provisions of table 6.

|

Rated voltage level(V) |

Power frequency voltage withstand test voltage (AC RMS value)(V) |

|

380 and below |

3000 |

|

660 |

3600 |

2.4.7 the electrical gap between the main chamber and the connecting cavity of the connecting cavity are in accordance with the provisions of table 7.

|

Voltage level() |

Electrical clearance(㎜) |

Electric distance(㎜) |

||

|

The main chamber |

Wiring chamber |

The main chamber |

Wiring chamber |

|

|

36 |

0.8 |

4 |

1.6 |

4 |

|

133 |

1.5 |

4 |

2.2 |

4 |

|

660 |

8 |

10 |

11 |

16 |

|

1140 |

12 |

12.5 |

18 |

22 |

The loss impedance voltage of the main transformer of the 2.4.8 integrated device is no load current, and the deviation of the transformer ratio is in accordance with the provisions of table 8.

|

project |

deviation |

|

No-load loss |

+15% |

|

Load loss |

+15% |

|

Total loss |

+10% |

|

Impedance voltage |

+30% |

|

Transformer ratio |

The +10% transformer ratio is less than 3 and the rest is + 0.5% + 1% |

2.4.9 integrated device casing shall be set with reliable mechanical interlocking and assurance in isolation switch is in the off position, main chamber door (cover) can be opened and in door (cover) is open, isolating switch can not be closed, the wiring chamber with the fastening screws can be installed power open cover "warning sign. 2.4.10 integrated device output power, within the enclosure of live parts (a) shall be additional protective insulation cover plate, and marked "live" in the words of warning signs.

2.4.11 is strictly prohibited to open the cover for maintenance, debugging!

Three, structure and working principle

3.1 structure overview

The explosion proof shell of the integrated device is a cylindrical shape, with a convex bottom and a cover. The shell cover and the shell body adopt the rotary cover stop structure. The upper part of the shell is provided with a junction box for introducing and leading out the cable. The right side of the shell is provided with a handle for operating the isolating switch and a test button for checking the validity of the short circuit and the leakage protection system. And a reliable mechanical interlocking device to ensure that when the isolation switch is closed, the shell cover can not be opened; when the shell cover is opened, the isolation switch can not be closed. A transparent observation window is arranged at the upper side of the shell cover, and the lamp can be observed from the outside. The connection of the main transformer and the movement of the terminal board is adopted, and the movement of the main transformer can be independently produced during maintenance.

Size and weight: 4.0KVA 480 x 690 x 615 (mm) weight: 128kg

3.2 working principle

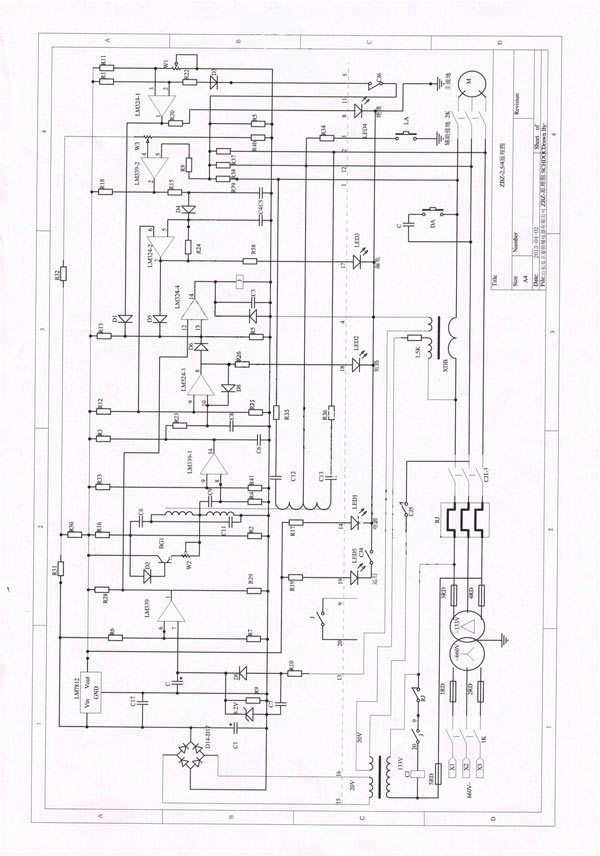

The electric circuit of the device is mainly composed of a main circuit, a control circuit and a protection circuit.

When the device is put into operation, the 1K is first closed, so that the main transformer and the control transformer KB have electricity to work, and at this time the light emitting diode LED2 (green) is electrically illuminated, and the device enters the working state to realize the purpose of 127V lighting.

Four, installation and use

4.1 in the maintenance and repair, is strictly prohibited charged open! No damage to the explosion surface! The introduction of the device must be compacted!

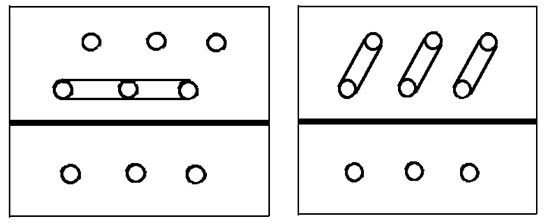

4.2 wiring way: the factory product main transformer according to 660/133V (or 1140/133V) way connection. If the 380V (or 660V) network work, the main transformer will be moved out of the shell, as shown in Figure 1.

4.3 the use of the wrong action or press the test button to produce a refusal, the replacement of electronic circuit board plug in test.

4.4 the equipment should be grounded reliably and the auxiliary grounding should be located 5 meters from the main grounding point.

4.5CJ contact has a certain life, serious damage should be replaced in a timely manner.

4.6 when the device is used in the underground, the contactor is strictly prohibited, and the three main contacts are short or the main contacts are forced to be closed by mechanical force, otherwise the circuit board plug will be burnt out.

4.7 continuous use of this product, each class should do a protective performance action test.

4.8 equipment should be carried out on a regular basis.

Figure 1 main transformer wiring diagram

Five, failure analysis and discharge

|

fault |

Reason |

Treatment method |

|

Closed 1K appear |

1, there is leakage fault |

1, find the cause of the failure to deal with |

|

Closed lighting handle switch 2K |

1, three-phase current serious imbalance |

1, find out the reasons for processing |

|

Can lighting, but after a period of time does not play the phenomenon of drilling, the lights are in normal condition. |

Thermal relay RJ action, serious overload phenomenon |

Find out the reason or change the lighting fixtures used in this device. |

|

Leakage test or short circuit test failure |

1, check the button SK1, SK2 is in good contact with |

1, find the cause of the failure to deal with |

|

Closed 1K power indicator light is not bright |

1, FU5 - FU1 has the phenomenon of fusing |

1, check fuse FU |

Six, packaging, transportation and storage

6.1 after the inspection of qualified products should be together with the technical documents into the plastic bag, and then into the packing box, the packaging should be firm and reliable.

6.2 along with the technical documents provided products and accessories.

A) product qualification certificate or quality assurance;

B) a description of the use of light distribution curve and efficiency data;

C) packing list;

Accessories, bags and accessories, D.

6.3 the packing of the product shall meet the requirements of transportation and handling, and shall ensure that the products are not damaged during the normal transportation.

6.4 the outside of the product packaging box with the words and signs:

A) product name and model;

B) the main technical characteristics of the receipt, delivery unit name and address;

C) packing quantity;

D) the "long and wide" size of the packing box;

E) "handle with care", "keep dry", "up", such as goods shipments "sign.

F) pack years

Name and address, post code of g;

Net or gross weight, kg h);

(I) receiving unit name, address (zip code) and arrival;

6.5 in the process of transportation packing box not inverted, to put, shall be subjected to strong turbulence, vibration, collision and snow or rain.

Products should be stored in the absence of rain and snow invasion, good ventilation conditions, air does not contain acid, alkali and other corrosive gas or dust.

6.6 stored in the environment (0-40) C, dry, clean and well ventilated, non corrosive medium in the warehouse.

Seven, maintenance and after-sales service

7.1 factory responsible for the maintenance of the product.

7.2 this product customer service quality problems within 8 months (human factors) is responsible for replacement.

7.3 this product warranty within two years, to provide technical services for life.

7.4 factory is willing to provide users with technical advice and technical training services.

Service telephone: +86-0537-6207766